Reflective Surfaces for LIDAR

Introduction

LIDAR is a method for measuring distances (ranging) by illuminating the target with laser light and measuring the reflection with a sensor. Differences in laser return times and wavelengths can then be used to make digital 3-D representations of the target.

Its core principle is the time-of-flight principle, which is extremely simple. However, the figures used for illustrating the time-of-flight principle often look confusing. They look as if all the emitted light was reflected and received by the receiver. This is, however, not possible in practice.

Some LIDAR video tutorials are also illustrating LIDAR in a similar way, which is confusing as well.

In this blog post, I would like briefly discuss the effect of different reflective surfaces for LIDAR.

Reflections

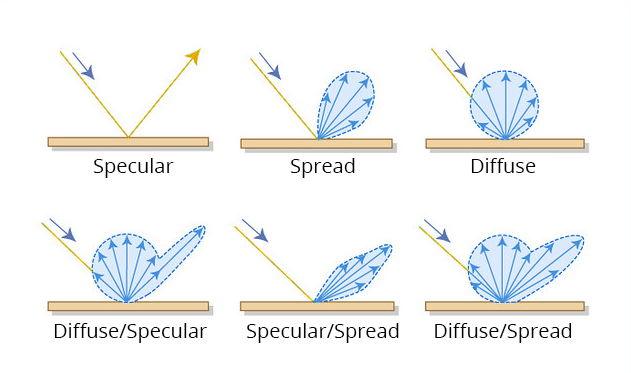

In practice, the reflection could have the following scenarios, depending on the type of the surface.

This means that the reflected light that LIDAR receiver receives is only a small portion of the emitted light. Given the noise and the reflections from natural lights, the signal processing becomes more important and sophisticated I think.

Caveats

LIDAR is not always reliable. For example, if the surface is specular, then it is almost impossible for the receiver to receive the reflected light. Then the target becomes invisible to LIDAR.

References

Reflective Surfaces for LIDAR